2018 – 2025

RESPONSIBILITIES:

Design and development for Rome snowboard boots. Communicating designs with technical packages , material selection, on snow testing, manufacturing QC, and packaging design were responsibilities I had while working on boots.

TASK:

Design, develop and execute an organized line of boots with tiered levels of price and performance.

GOALS:

Incrementally improve existing boots through material selection and manufacturing improvements. Apply the Rome brand identity and visual language created by the graphic team to the boots using innovative and tested techniques.

RESULTS:

The Rome boot category has remained a success and are recognized as highly durable and well fitting boots that keep you on hill for longer.

DESIGN DETAILS

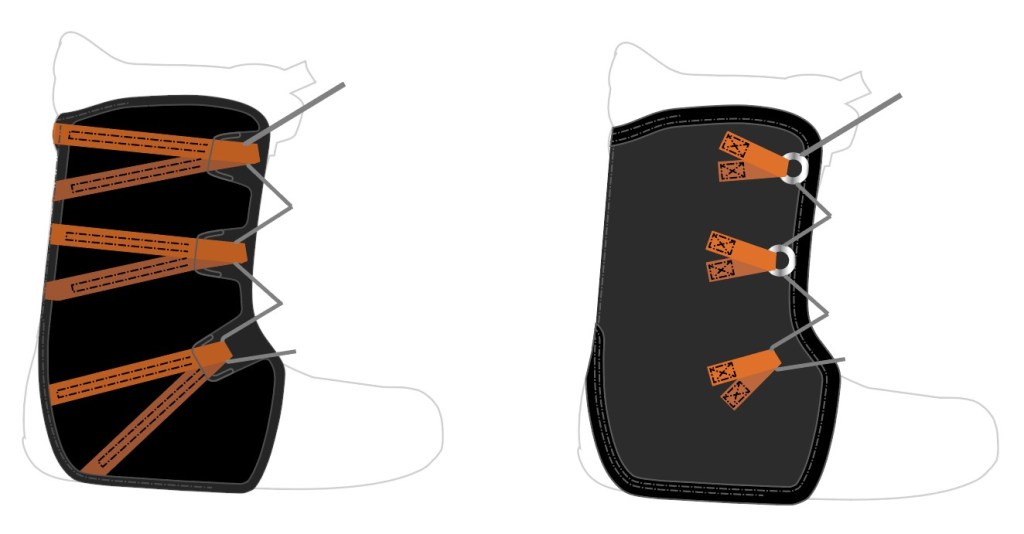

Lacing configurations offered on the Libertine line.

2425 Libertine Boa, Libertine Hybrid Boa and Libertine Lace

ANNUAL LINES

Every year we delivered a line that was better than the last. Whether it was an addition of a new lacing option, addition of a colorway or an improvement of materials, the sales grew and the reviews remained positive.

DEVELOPMENT

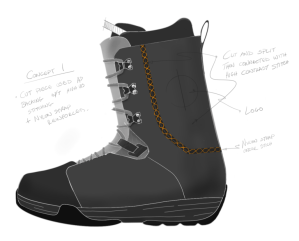

Sentry boot concepts.

Stomp Boa and Stomp Lace technical drawing used for samples.

INCREMENTAL IMPROVEMENTS

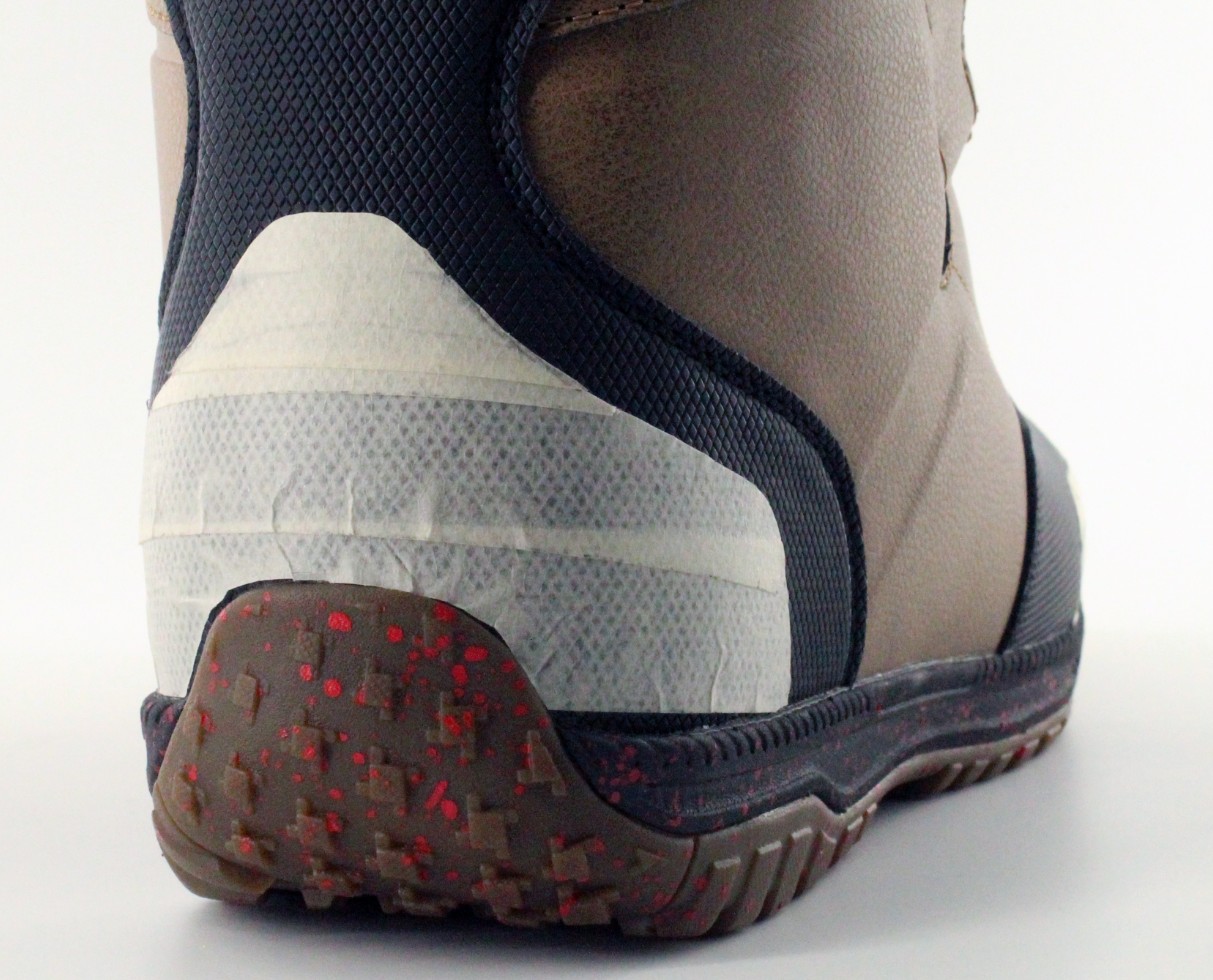

Toe cap and heel stay reinforcement pattern development with tape.

Production boot with TPU hot melt on toe cap and heel stay to improve abrasion resistance.

Power strap development and production.

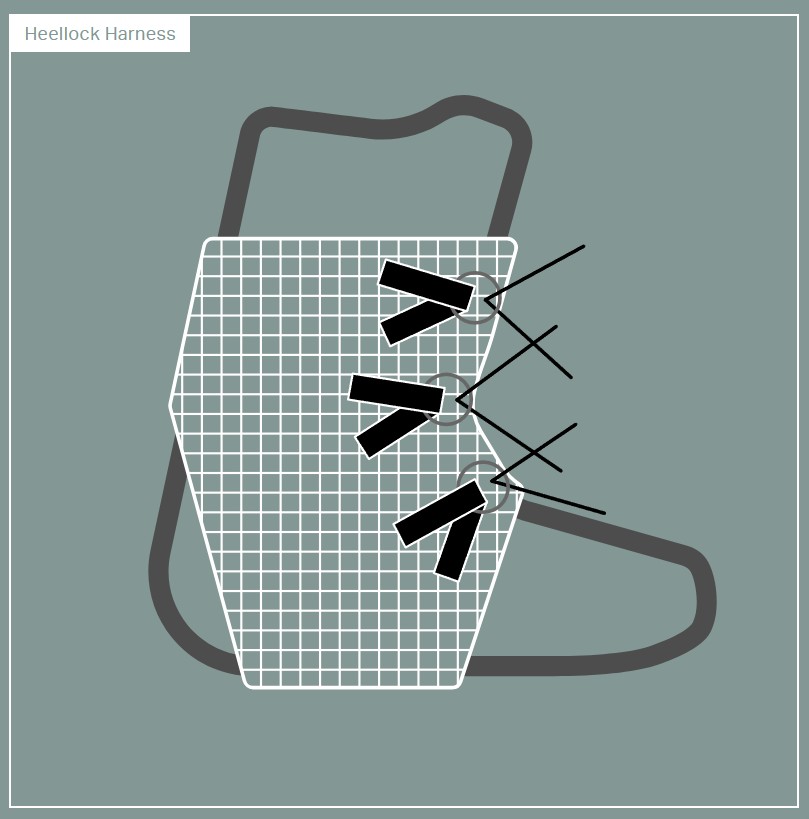

A common critique is the lifting of the heel while riding. The heellock harness solves that issue!

TESTIMONIES AND REVIEWS

– Whitelines.com

“The quality on display here is irrefutable, and will please even the most demanding rider.”

– Whitelines.com

The more comfortable the boot, the more time spent on the slopes!