2018 – 2025

RESPONSIBILITES:

Design and development of highbacks, buckles, straps, EVA textures and size grading for all chassis. Primary 3D surfacer for all components, on snow testing, manufacturing QC, and packaging design were addition responsibilities I had.

TASK:

Design and develop a new line of bindings for Bataleon that would be manufactured in parallel with Rome bindings.

GOALS:

Apply the Bataleon brand identity visual language to all components to differentiate the two brands.

RESULTS:

The Bataleon binding category launch was a huge success with continued year-over-year growth. The designs created have helped to influence continued design efforts in this category.

DESIGN WORK

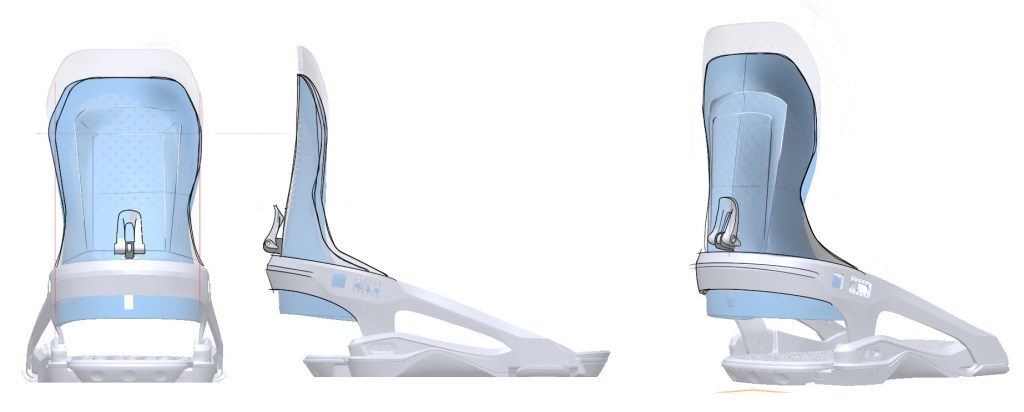

Design Language

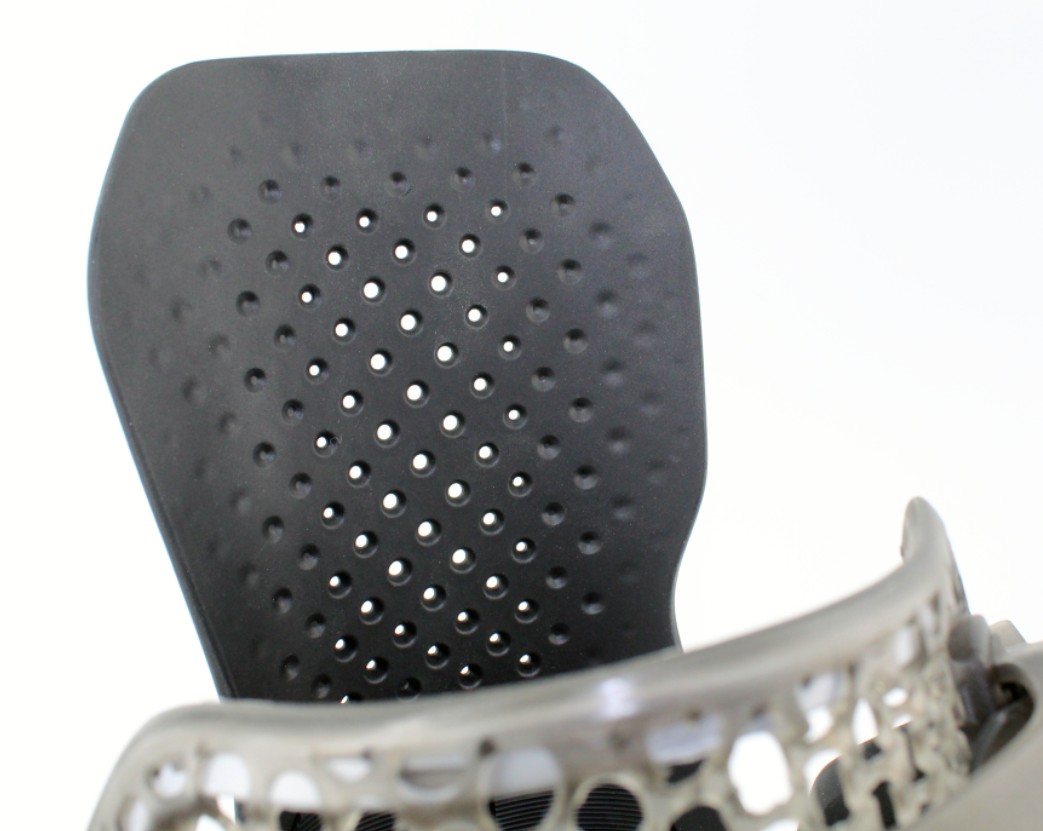

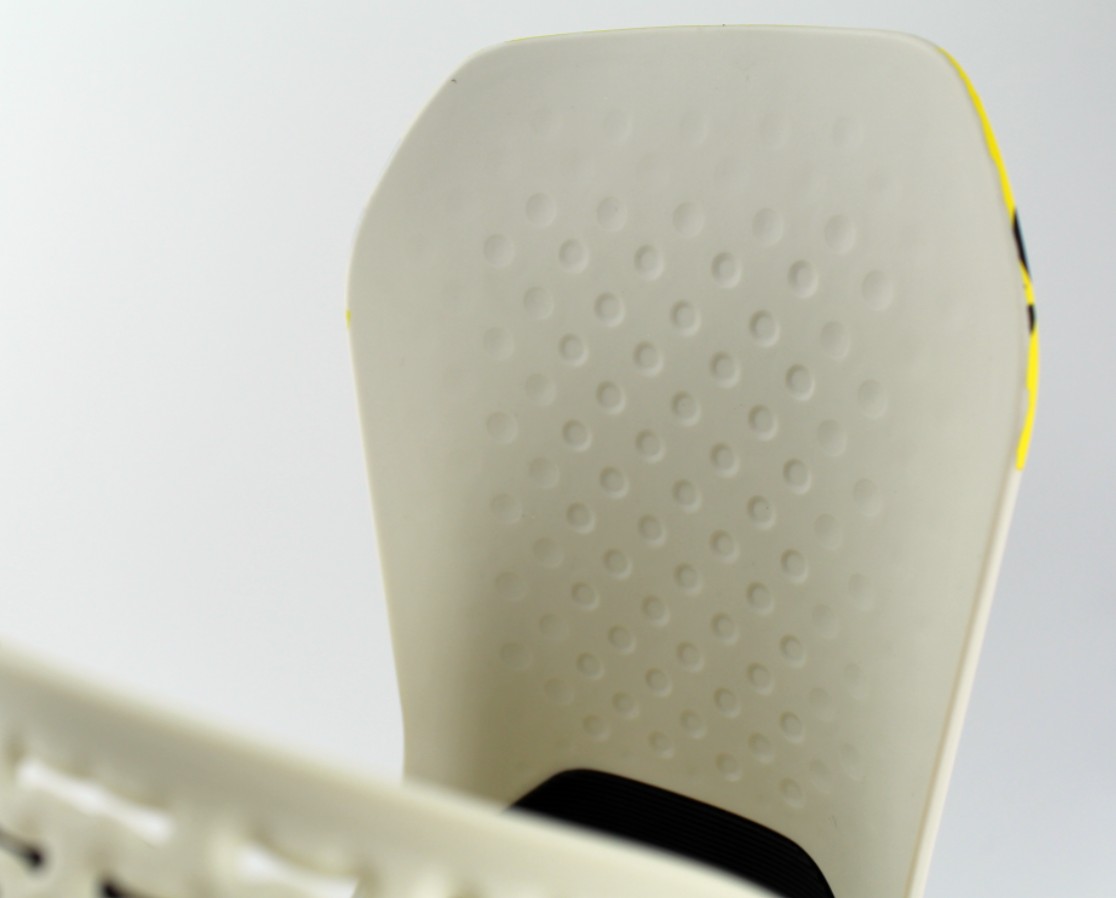

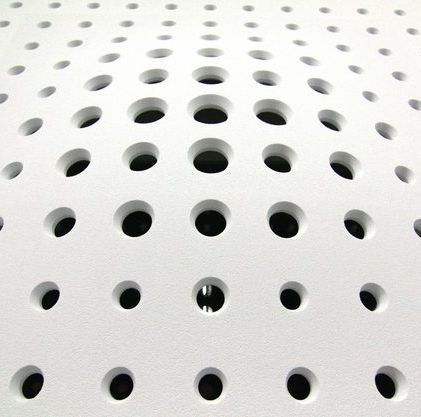

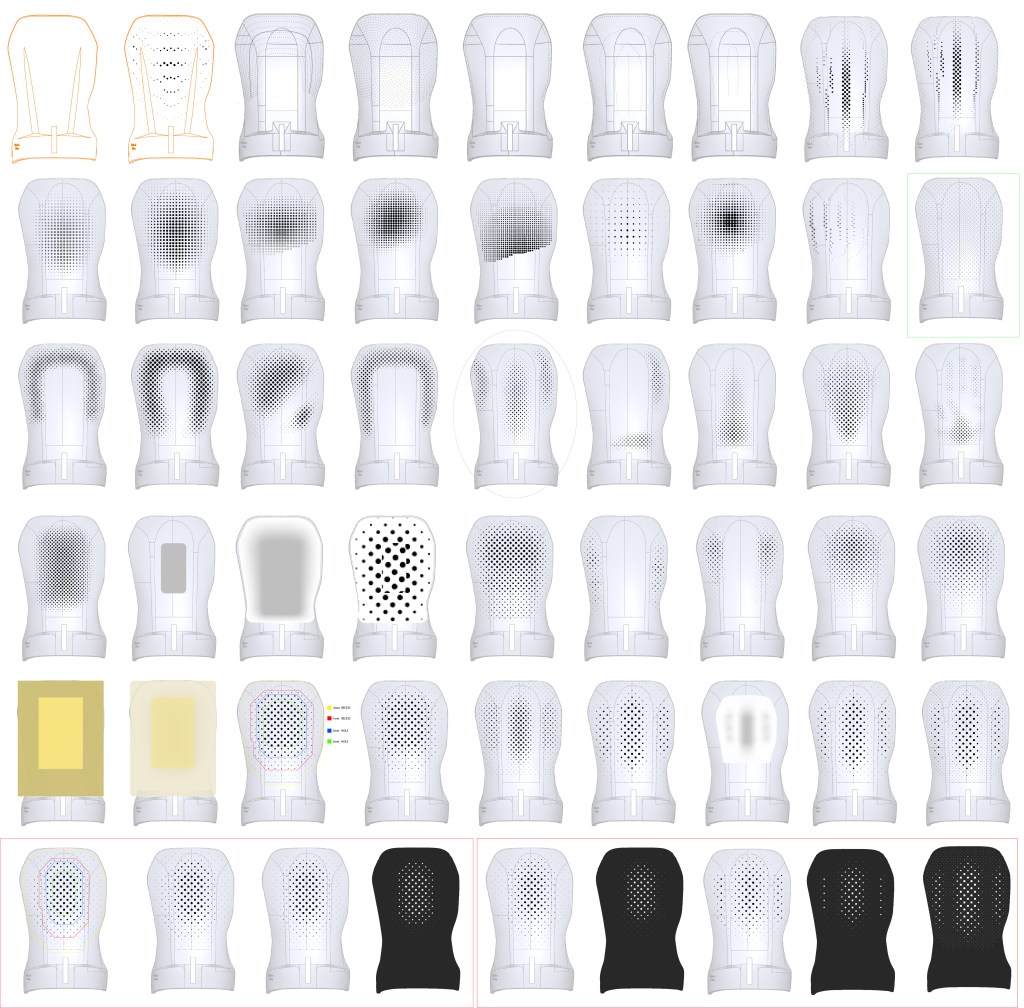

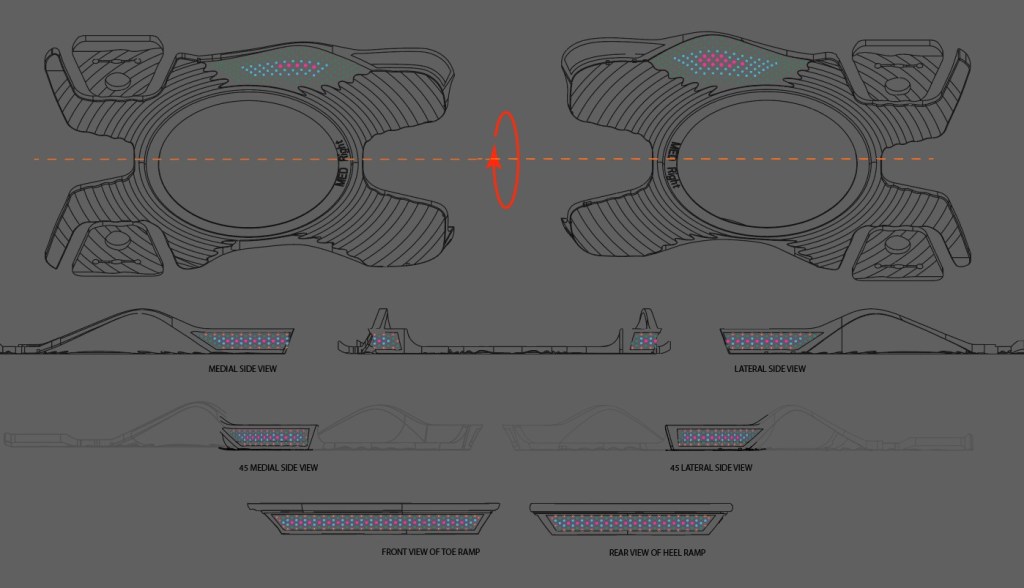

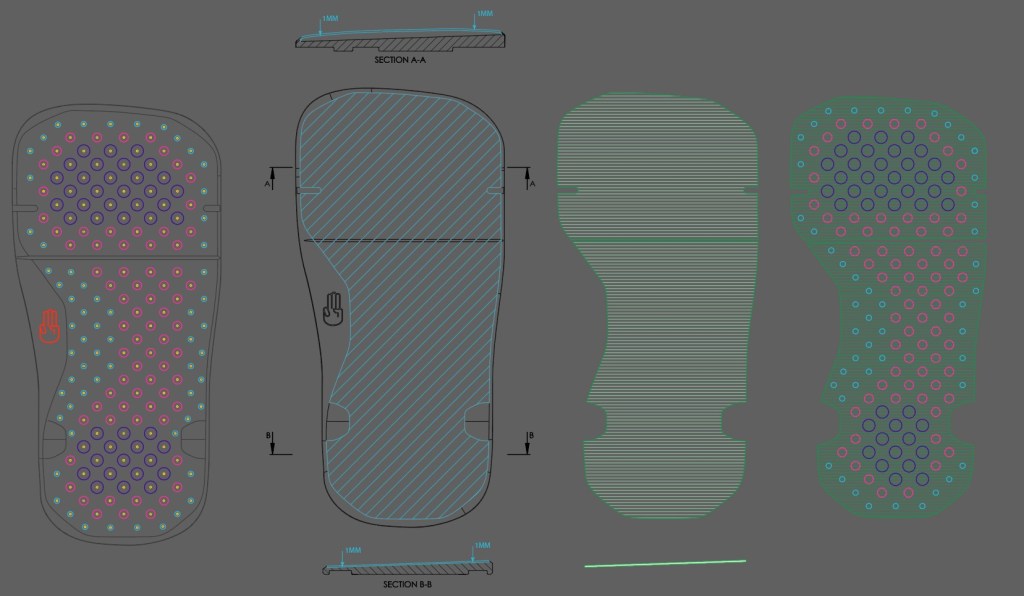

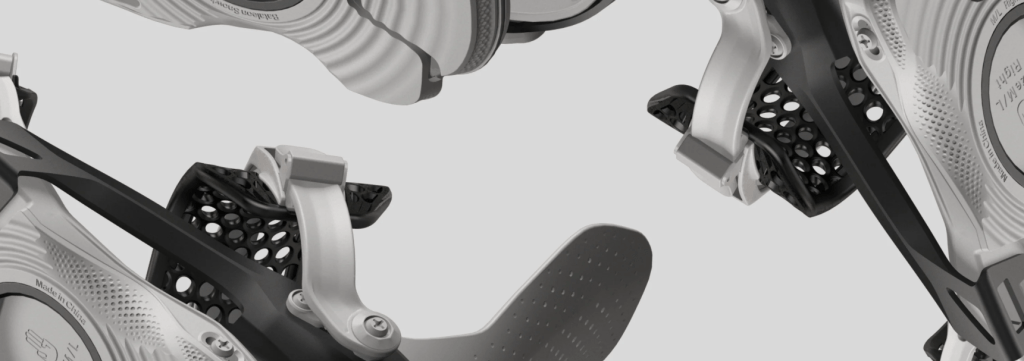

Ripple, lines, holes and dots were used as to represent the visual language of the Bataleon line of bindings. My role was to build the patterns and apply it to all 3D parts.

Texture Inspiration.

Texture pattern exploration sketches.

EVA padding layout/design.

Footbed padding texture design.

Binding Part Development

A number of components were designed to follow the brand identity of Bataleon. Buckle levers, straps and highbacks all followed the established language of the Bataleon brand.

Brand Identity Execution

Bataleon is a loud and proud company. The goal was to work with the graphic design team at Bataleon to create bright and loud branded bindings. During this work, we explored a number of manufacturing techniques and experiments that lead to great results. Anodized heel hoops, water decals and alternative painting techniques were perfected every year.

TESTIMONIES AND REVIEWS

“We love the clean industrial design, and they perform as well as they look.”

– Whitelines.com

– Whitelines.com