ECONOMIC CHASSIS FOR ROME & BATALEON

2022

RESPONSIBILITIES:

Design and development, primary 3D surfacer, prototype builder, on snow testing, manufacturing QC, and size grading to multiple sizes.

TASK:

Design and develop a lower cost binding assembly while maintaining performance.

GOALS:

Maintain the high level performance and durability as our other bindings. Fit the design of the binding into the aesthetic of the current line of Bataleon and Rome products.

RESULTS:

The heelwrap chassis has been a great success and continues to be a favorite of many customers and pro riders due to it’s performance, light weight and “Box-to-Board” design.

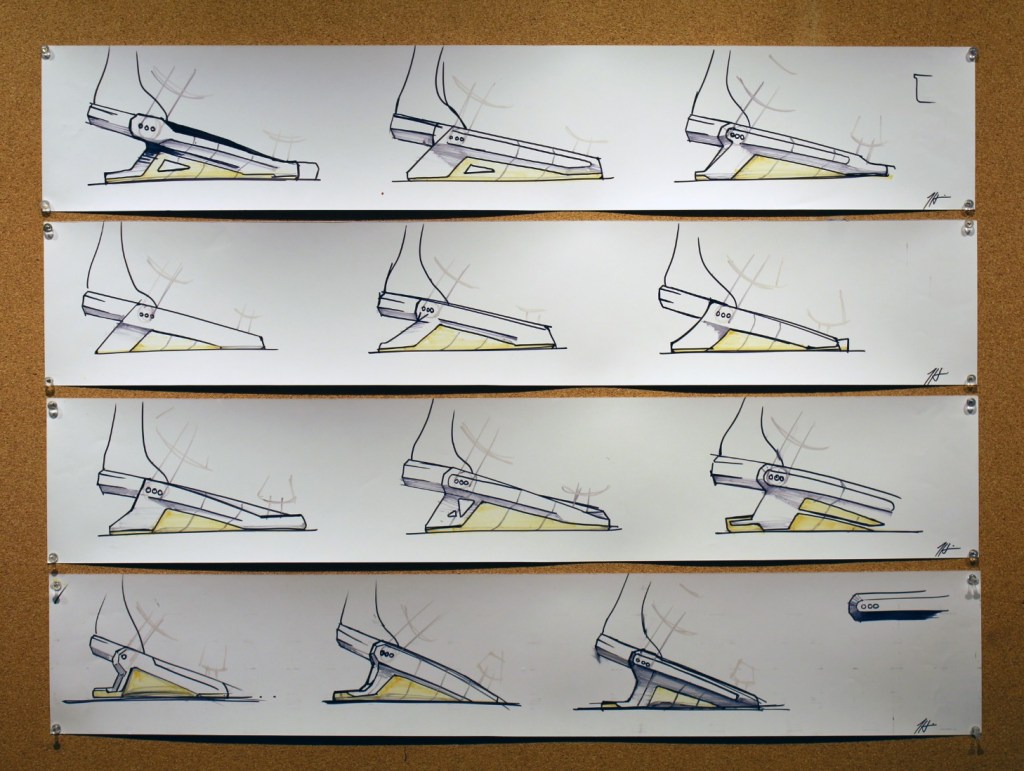

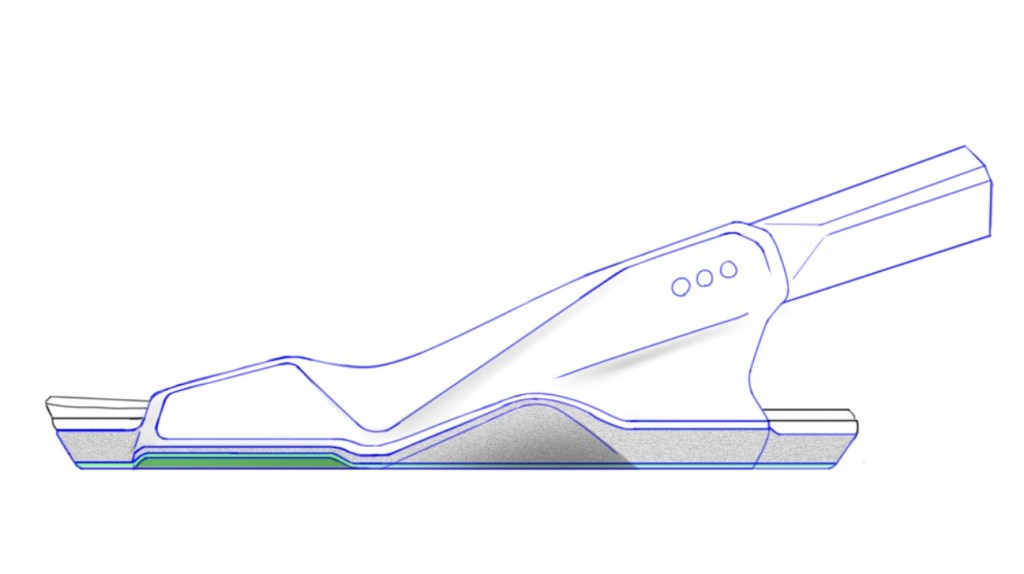

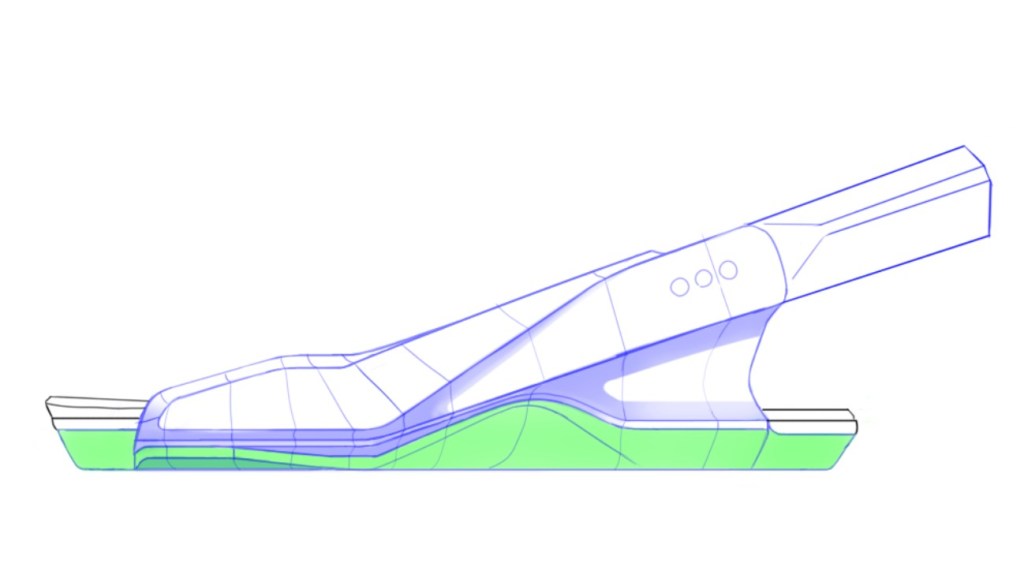

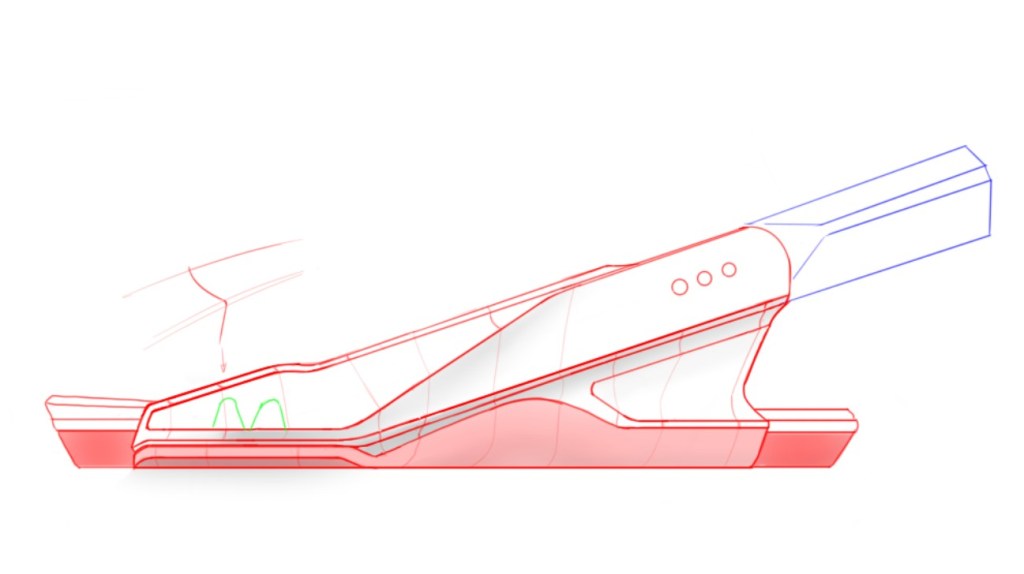

Detailed profile drawings.

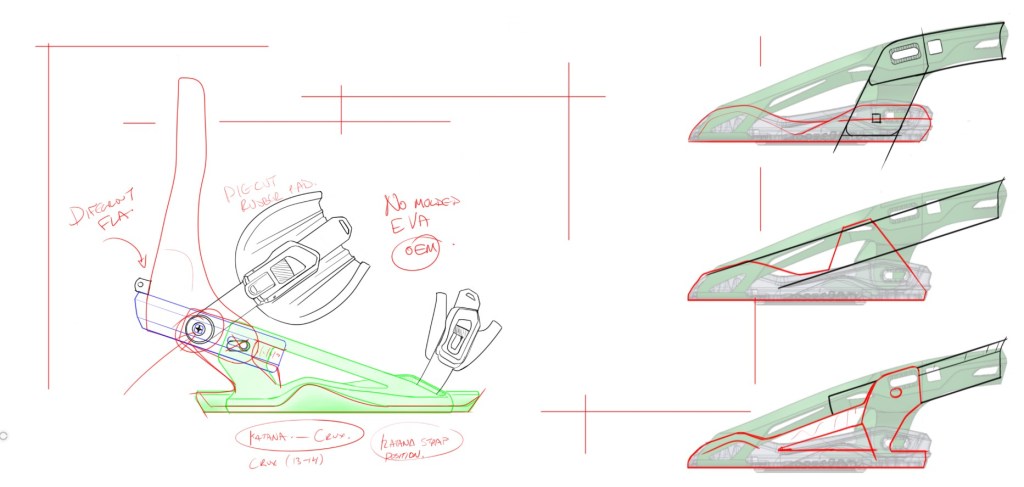

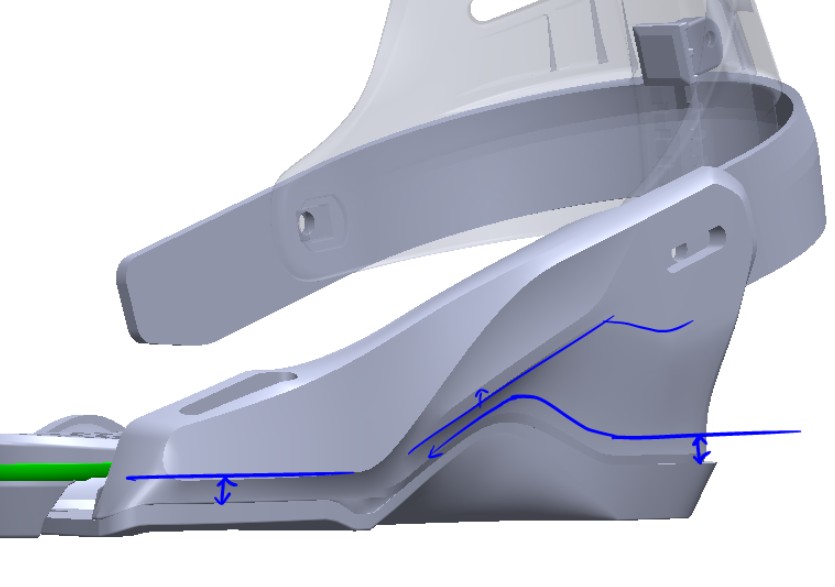

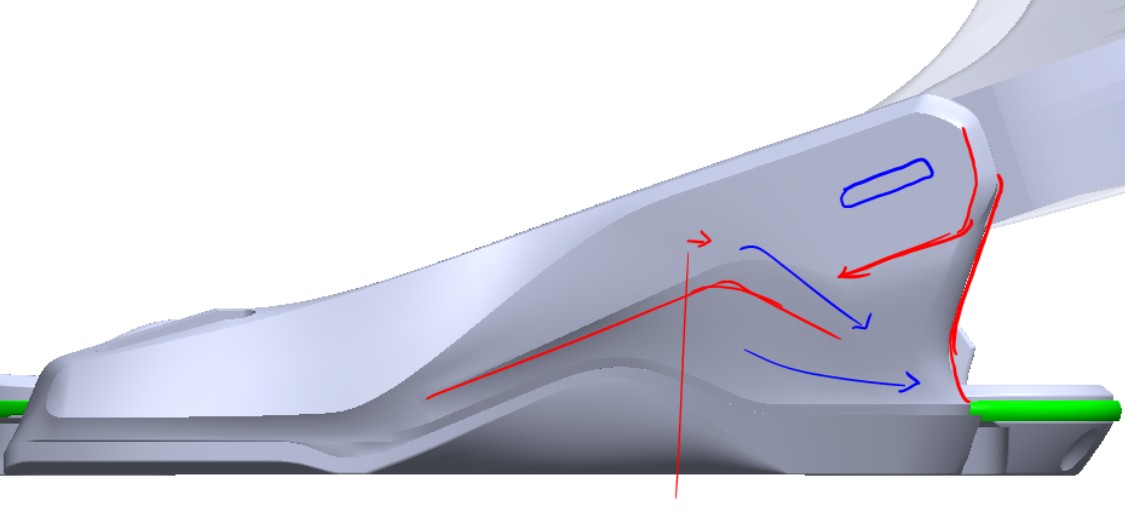

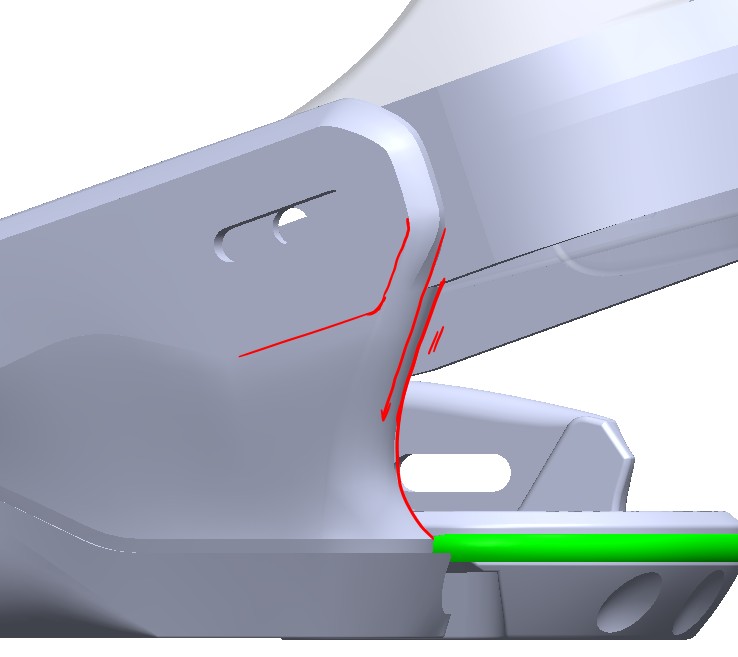

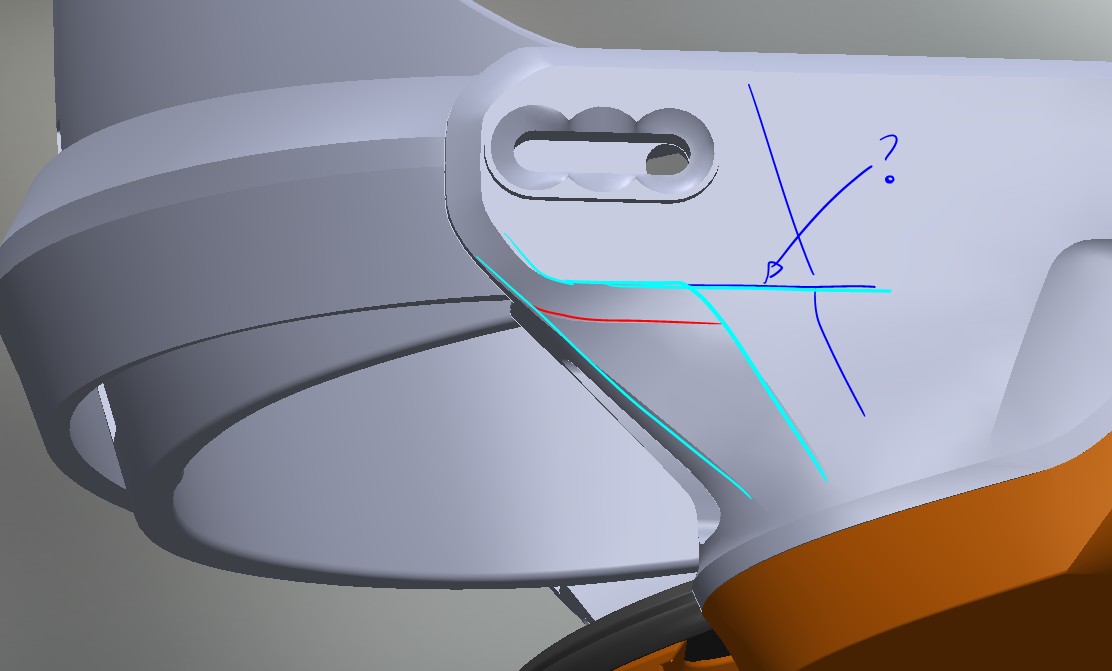

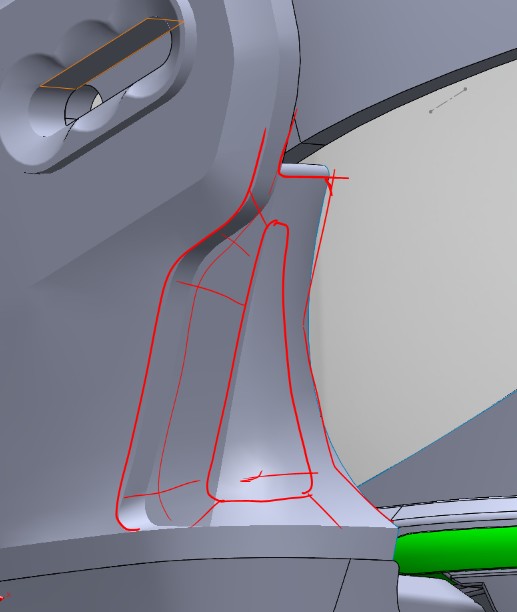

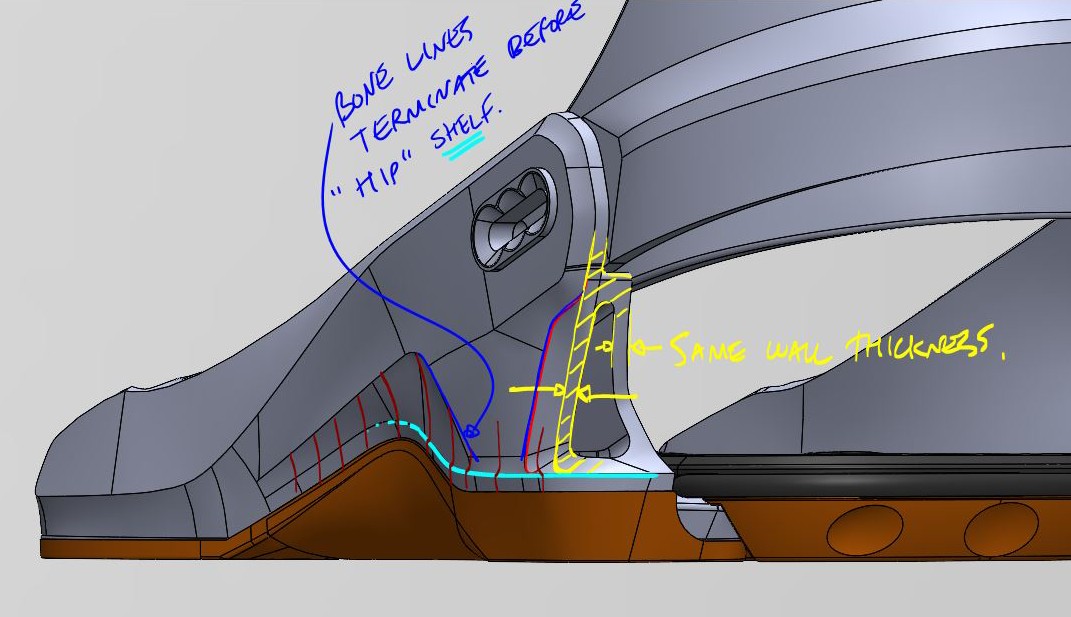

3D Surfacing adjustment comments.

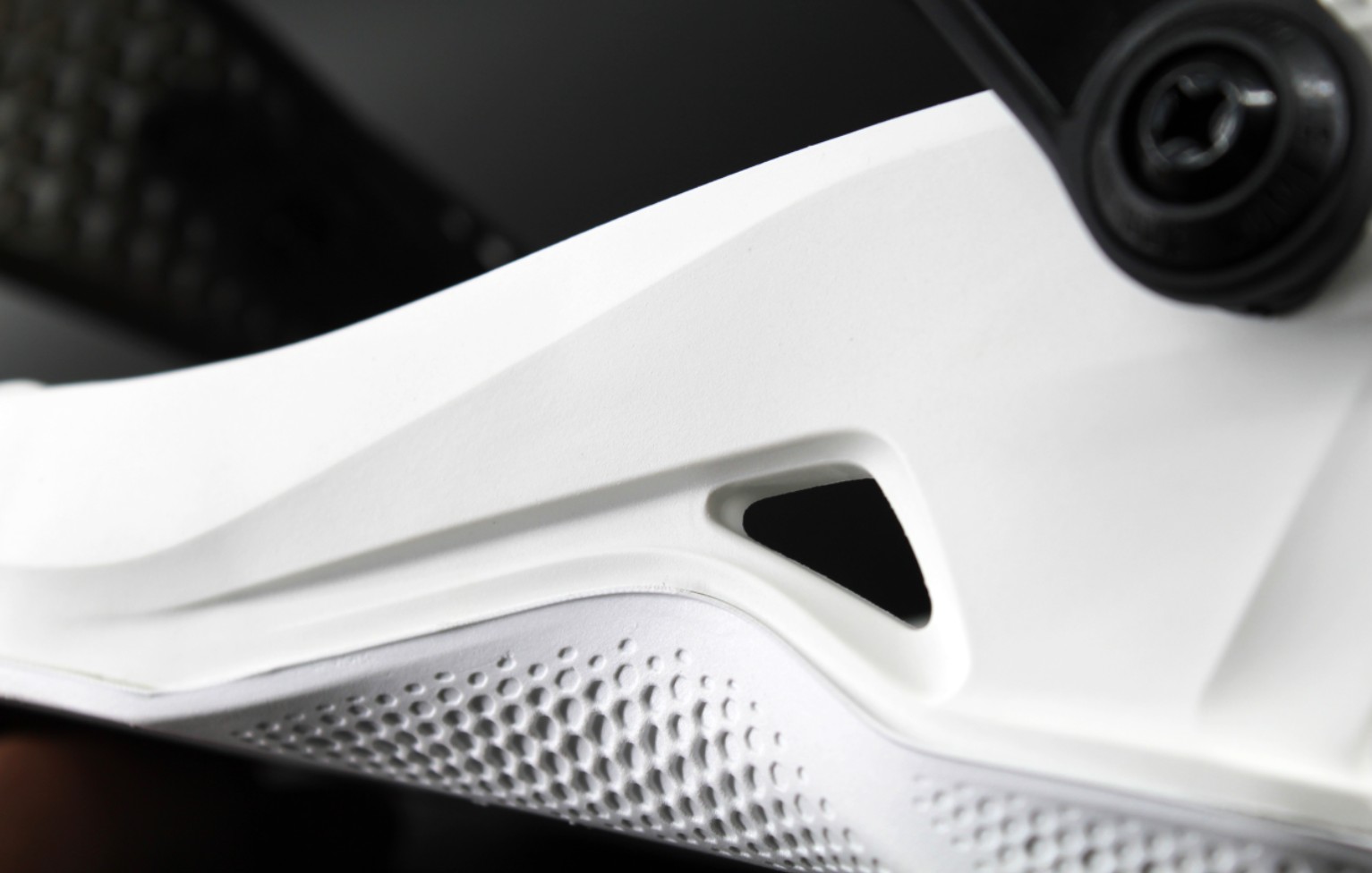

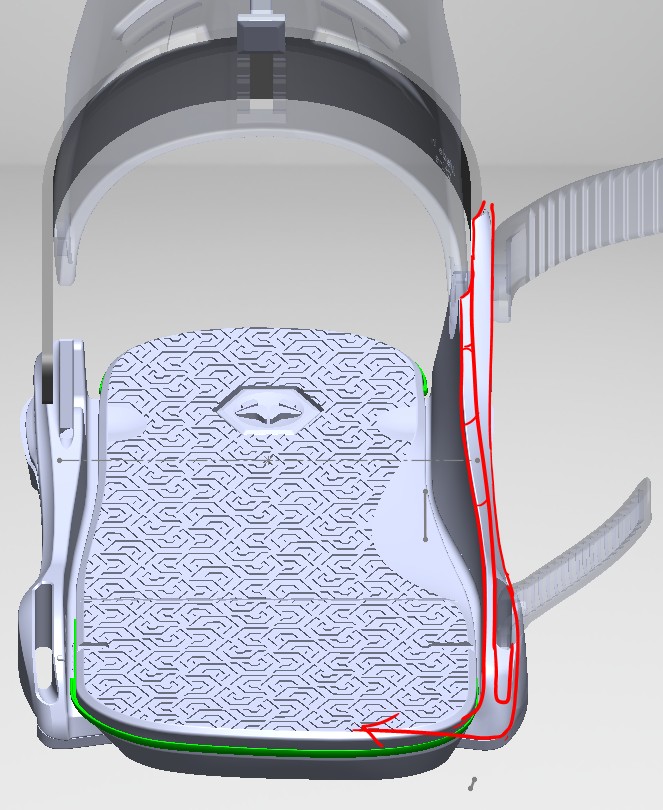

Form and surface adjustments on 3D prints.

Strap and size adjustment geometry exploration.

Nylon SLS 3D printed ridable prototypes – did not break